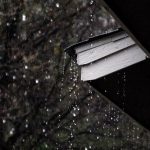

Roof flashing is an essential component to prevent leaking through your roof. The flashing acts as a diverter between the joints of certain roof areas, which is an efficient way of keeping water out.

Some areas of your roof and walls can be more susceptible to leaks and water damage. For example: dormers, roof valleys, skylight perimeters, and the chimney areas. Wherever water runoff is heavy or two surfaces meet, they will need a little extra attention by way of roof flashing.

7 signs of damaged and leaking roof flashing

Materials Used for Flashing

Popular materials used for roof flashing include galvanized flashing, copper and aluminum. The most commonly used material for roof flashing is pre-painted sheet metal. Galvanized flashing is usually used by homeowners who like to install their own roof flashings.

Roof Flashing Types

Flashing is most often formed through soldering, though there are a variety of different kinds of roof flashing. Chimney flashing will be used at the base of the chimney in multiple parts. There will be flashing around the bottom, step flashing around the sides, and finishing with saddle flashing around the top. Additionally, when roof flashing around the chimney, one can use a cap flashing to lap over the edges of the rest of the flashings to keep water out.

In the case of a vertical wall or a sloped roof, one will need to use step flashing. Drip edges will stop any water from trying to seep underneath the roof around the eaves. Around skylights, integral flashing is used as well as step flashing around the base, the sides and the use of saddle flashing around the top.

The most common areas where leaks occur are where pipes are penetrating the roof surface or the flashings in valleys. These areas should be sealed with special asphalt roofing cement. In order to prevent leaking around areas with pipes, one should invest in vent pipe flashing (there are several options for this). This will stop leaking before it ever happens.

Roof Flashing Structure and Purpose

Roof flashing materials are waterproof. You may see roof flashing made from plastic, rubber, but it’s usually a rust-resistant metal such as:

- Galvanized steel – used most often and preferred by professional roofing companies

- Aluminum-zinc coated steel marketed under the Galvalume name – offers more corrosion resistance than galvanized steel

- Aluminum – easily bent and the material of choice for DIY installation

- Copper – custom-made for copper roofs

Roof flashing is installed wherever there’s an intersection or a termination of your roof. That means you’ll see roof flashing material in the following areas:

Roof flashing is installed wherever there’s an intersection or a termination of your roof. That means you’ll see roof flashing material in the following areas:

- At vent pipes

- Along the eaves and edges of the roof

- In low areas (valleys) where roof pitches connect

- Around dormer walls

- Around skylights or other things that extended from the roof

For flat roofs or those without overhanging eaves or soffits, drip edge flashing may be installed to move water off the roof into a gutter system.

Damaged Flashing

Since flashing occurs at your roofs most vulnerable areas, it’s not uncommon for it to be damaged. However, damage can occur in several ways, like cracking, warping or being torn away completely.

Flashing may become damaged because of poor installation, poor repairs, age, and exposure, as well as weather-related issues. The most obvious way to determine if your flashing is damaged and in need of repairs is if a leak reveals vulnerable areas.

Although shingles are the primary protectors of your home’s roof, they can’t completely seal joints or corners. Roof flashing may be thin and flat, but it plays a mighty role in keeping water from damaging your home. Signs of roof flashing damage range from minor, hard-to-spot trouble areas to major breaches requiring significant repair. Here are issues to look for:

- Small holes: Water needs only a little space to seep under roof shingles. Small holes in roof flashing caused by corrosion or wildlife (woodpeckers) can turn into a large problem and need to be sealed.

- Rust or corrosion: Even with galvanized coatings, roof flashing materials will corrode over time due to the reaction with air. Salt air is more corrosive than inland air. Rusted roof flashing will no longer repel water and needs to be cleaned, sealed or replaced.

- Missing pieces: If roof flashing loosens during storms or high winds, is not affixed properly, or is peeled back by a curious raccoon, you may notice missing pieces. The absence of water barrier flashing makes this a high priority repair.

- Bends, cracks or dents: A bend or crack seems minor, but this type of damage breaks the galvanized coating on steel or weakens the structure on other metals. When the metal is compromised, it can be more susceptible to corrosion.

- Internal leaks: You may not be able to see all the roof flashing, but internal leaks near windows, fireplaces, skylights or in your attic are another sign of damage.

- Mold or staining on fascia boards: Drip edge flashing that was improperly installed can cause this type of mold and staining damage.

- Worn or damaged siding or shingles: When the roof flashing fails to deflect water properly, you may see water damage on the siding. Shingles in low spots or near areas where flashing is used may show signs of water damage (darkening, bending), indicating the roof flashing material has been compromised.

Assessing Roof Flashing Damage

Since roof flashing is usually made with metal, it appears to be sturdier than shingles or tiles. It is designed to be tough. But over time, roof flashing material can show signs of wear and can be damaged by acid rain, wind, hail, severe heat, and heavy snowfall. In coastal areas, exposure to salt air can also affect roof flashing.

Take time to visually inspect your roof in the spring to evaluate any damage from winter storms. And review it again in the fall to determine if repairs are needed before another winter arrives. While your visual inspection from ground level is a good starting point, consider hiring a professional roofer. Their expertise ensures damage will be found, and they’ll provide recommendations for necessary repairs.

Working with a Professional Roofer to Repair Roof Flashing

You’ll find multiple online sources of DIY advice about how to repair roof flashing. Working on roofs, even on single-story buildings, is dangerous. Professional roofers have the expertise to safely navigate, identify problem areas and make accurate repairs. Contact our team at Warner Roofing if you notice flashing damage or would like us to conduct a roof inspection. You can count on us for exceptional service.